At Komaki plant that was completed in September 2014, we have produced "low pressure turbine blade" is a part of the aircraft engine.

The mainstream of the aircraft engine's turbine type, the high pressure air taken from the outside by the compressor, combustion by injecting fuel into it, rotate the propulsion fan in the energy of the generated high-temperature and high-pressure gas, and get repulsive force ejected backward.

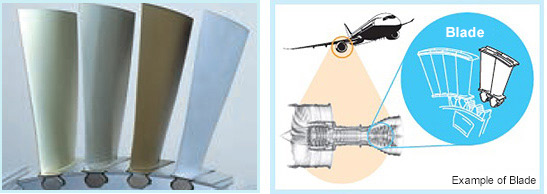

This conversion from energy to rotational energy of the high-temperature, high-pressure gas is carried out turbine (impeller / rotary machine), this turbine consists of many "blades".

Because "Blade" has exposed to the harsh environment that high-speed rotation while receiving a large force in the hot gas jet, it has become a high-precision and high processing difficulty parts due to heat-resistant alloy of high-strength.

Consistently processing is to do literally the processing steps all in house "blade".

Aircraft engine parts are required to conform to Nadcap(certification of the special process of commercial aircraft field), a strict process authentication in the process step, high technology is has been required.

Special process that specializes in the Company(welding, electrical discharge, surface treatment, nondestructive inspection etc.) to the center, by to meet the needs of customers that tend to increase in the future to establish a building that was part of aircraft engine parts manufacturing required high quality and technology management, we will continue to contribute to the aircraft industry.