Electrical discharge machining is one of the method of processing the metal.

In contrast with general machining that is a method of processing metal with knife having substance such as lathe or drill, electrical discharge is a method of processing a metal by electrical energy.

Electrical discharge was invented by the Razarenko and his wife in the Soviet Union during the 2nd World War.

Originally they had a research for preventing wear of the contacts of the switch due to sparking (discharge phenomenon), while conducting research, they got the reverse idea, it'll be able to process metal by utilizing the discharge phenomenon rather than prevent it.

Research of electrical discharge machining began from then.

Circuit for generating discharge they developed is called Razarenko circuit by taking name of the couple.

In Japan, research began from after the early days of the 2nd World War, the No.1 electric discharge machine domestic was born in March 1954.

(The development of the first unit, Shoji Futamura of our founder also participated.)

Where the first unit was produced (Takatsu-ku, Kawasaki-shi, Kanagawa-ken), has become the site of the Kanagawa Science Park (KSP) now, the stone monument as "the land of the electric discharge machine birth" has erected.

A small thunder to the metal artificially dropped, and then processing the metal by its energy.

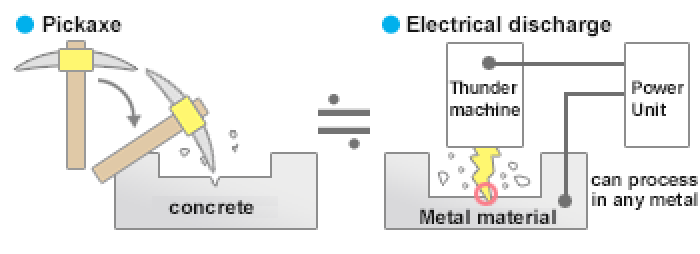

Please try to imagine the people who are digging a hole with a pickaxe at the construction site.

Does not dig a lot at a time, will spread hole steadily that down also swing the pickaxe many times.

In the electrical discharge machining, thunder play a role in this pickaxe.

In the electrical discharge machining, by shoot again and again a little thunder, it shave the surface of the metal in the heat and shock (1,000 ~ 100 thousand / sec), and gradually change the shape.

Not afford to cut in two with a knife or drill at one, instead it can process the complex and fine shape.

In addition, an ordinary blade isn't able to process hard metal than the hardness of its own, but the thunder can process even a very hard metal because hardness does not matter.