Direct drive digital servo press "ZENFormer" that was carried out to develop the concept of "high-precision machine tools comparable", as well as to achieve complete parallel control in its own new technology, achieved an overwhelming high-precision machining of the nano-level Did.

"Ichimura Work Award", "The new Machinery Promotion Award", "Monodzukuri Nihon Award" and "MF technology Award" has received as many awards.

"ZENFormer" series, also supports custom design to meet your needs.

In addition, we have also to a wide range of correspondence to the request of the maintenance and custom.

ZENFormer

MPS8300DS

MPS8600DS

MPS81000DS

Model

Double slide (double acting)

Nominal force (inner + outer) ~9800kN

|

MPS4100

MPS4200

MPS4500

Model

Single-Slide

nominal force ~4900kN

|

MPS405UD

MPS410UD

MPS420UD

MPS430UD

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||

- We can consistently processing to delivery from the purchase of material.

- Available upon contract processing also happily in semi-finished products and prototypes.

- Equipment sales in conjunction to the processing content and corresponding to meet the customer's needs is possible.

- We developed the servo press machine of high precision and high efficiency of the world's highest level.

- We proposed the new method development and man-hour reduction plan due to the high precision servo press.

- Not only sale of press machine, can be manufactured prototypes and mass.

ZENFormer:Achieve the overwhelming high precision ingenious new technology

Direct drive digital servo press "ZENFormer" realized the high-precision slide parallelism with fully using of the control technology we developed originally.

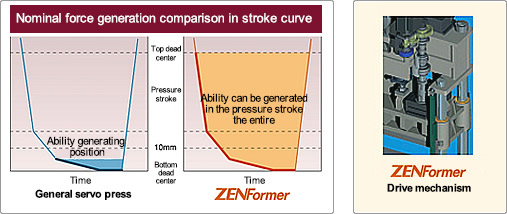

In addition it can generate the maximum capacity in pressure stroke the entire, and because processing speed can be varied at will, it make enable the complex high-precision processing in a wide range.

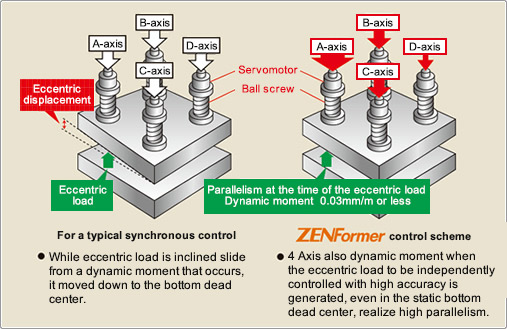

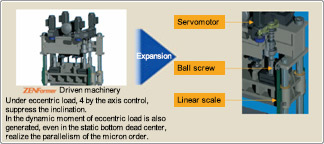

◇4-axis independent control / Feed forward control

- By each the installed linear scale to the four corners of the slide, the position of the four corners of the slide is measured constantly nanometer level always monitored.

- On the basis of the measured value, in the feed-forward control, the optimal command value, the instruction for each drive shaft, dynamic moment of eccentric load occurs, and achieve a high degree of parallelism in the entire area up to the bottom dead center.

- Under the parallel control, etc. to maintain a long-term continuous pressure state at a maximum pressure state, arbitrarily can be set for any motion.

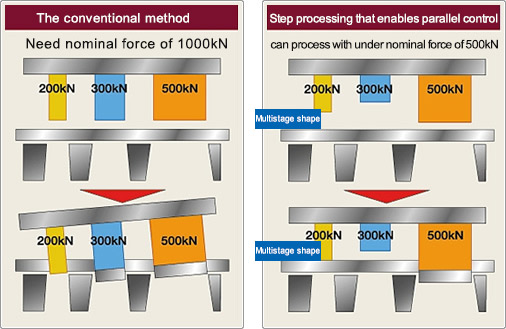

◇Realization of the full parallel control

- Direct acting by ball screw drive 4 axial pressure structure

- Suppressing the inclination under eccentric load, enabling high-precision stamping.

(ex.) In step processing, etc., even if the shaping load varies, it is possible to work with minimal equipment load.

◇ZENFormer Specification example

◇Adoption of the ball screw linear equation

- Achieve a dynamic accuracy equal to the machine tool.

- Setting the stroke length can be set freely.

- It is capable of generating the maximum capacity in the entire stroke.

- It is available parallelism maintenance of micron accuracy in during stroke and the bottom dead center.

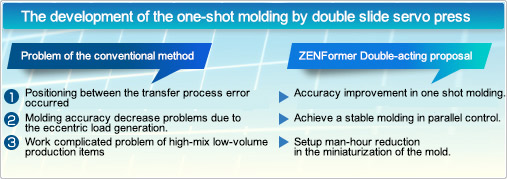

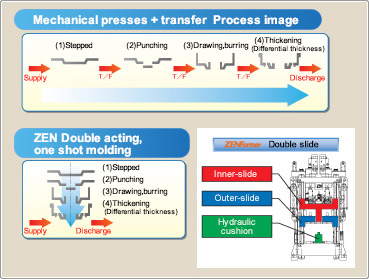

◇Realization of the Double slide servo press

- By the vertical slide the two-stage structure, capable of vertical direction of the process layout (shortening the process).

- Improve accuracy by one-shot molding and realize the type cost reduction due to downsizing of the mold.

- It can correspond to high-mix, low-volume production.

◇ZENFormer Double slide Specification example