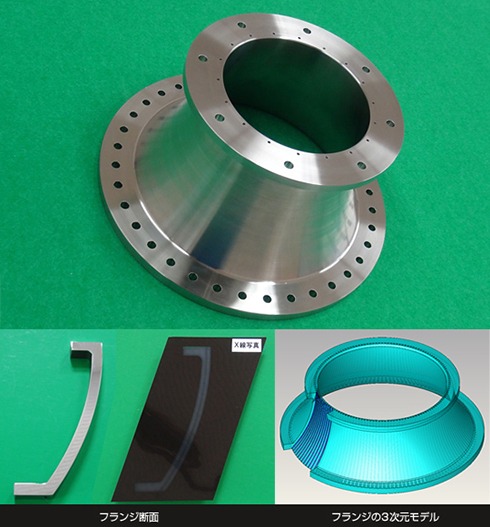

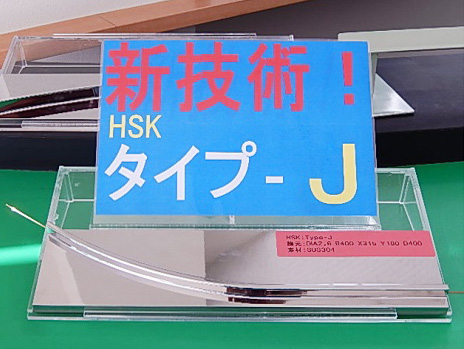

Curve hole machining is a new technology of the Company that can be processed a hole with a curvature(R).

Curved hole machining three types, the first technology can be processed at a constant R, the second the technology can be processed by combining two curvatures, the third the technology can be processed leading from the straight to R shape.

It should be noted, can be processed materials is stainless steel, Hastelloy, Inconel.

- We can consistently processing to delivery from the purchase of material.

- Available upon contract processing also happily in semi-finished products and prototypes.

- Equipment sales in conjunction to the processing content and corresponding to meet the customer's needs is possible.

- Processing track record over more than half a century.

- Japan's largest in the full-time of electrical discharge processing (metal working).

- It can be a wide range of support from micro processing to large processing.

- We realized the processing reform and cost reduction by developed in-house special-purpose machine.

Of the current stage processing technology

|

- 拡大

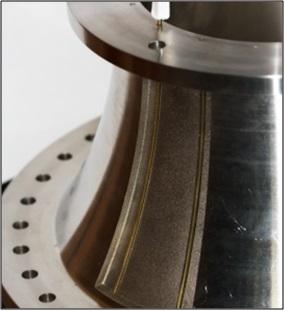

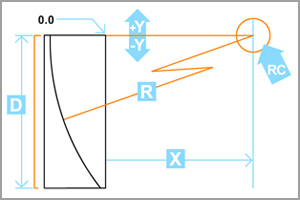

- Processed 1 type of curved hole processing.

|

|

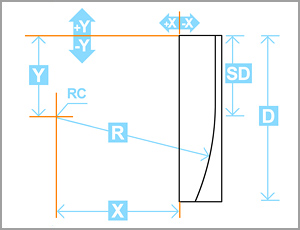

Specification sheet

|

※RC:center point of circle

|

- 拡大

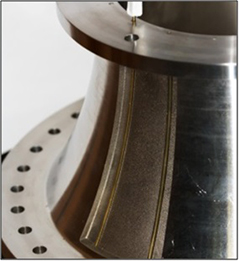

- Curved hole processed a combination of the types curved hole.

(We can process blind hole because it is the processing from the one-way.)

|

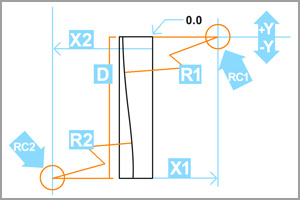

Specification sheet

|

|

- 拡大

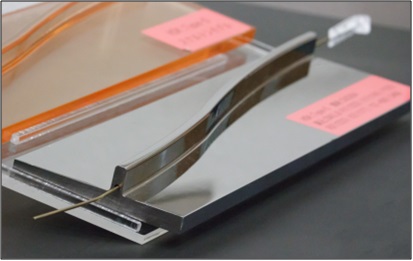

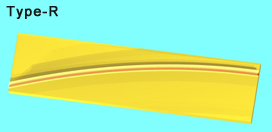

- the Curved hole processing of a combination of straight and curve

|

Specification sheet

|

*It is SD=Y.

RC: center of arc of Curved hole

|

"I would like to a combination processing like this, you can?" etc., please consult anything about Curved hole processing.

16th Kansai Mechanical Components & Materials Technology Exhibition

17th Mechanical Components & Material Technology Exhibition

|