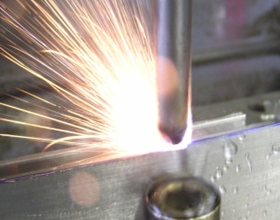

In the method of processing in accordance with the workpiece to the shape of the electrode, it is suitable for precision micro-machining of difficult-to-cut materials, from microfabrication of the micro level such as the slit of 0.02mm width to the ultra-large-scale processing such as a rocket engine nozzle skirt, this enables the precise three-dimensional processing of up to.

- We can consistently processing to delivery from the purchase of material.

- Available upon contract processing also happily in semi-finished products and prototypes.

- Equipment sales in conjunction to the processing content and corresponding to meet the customer's needs is possible.

- Processing track record over more than half a century.

- Japan's largest in the full-time of electrical discharge processing (metal working).

- It can be a wide range of support from micro processing to large processing.

- We realized the processing reform and cost reduction by developed in-house special-purpose machine.

- It can speed response by our own production of electrode.

|

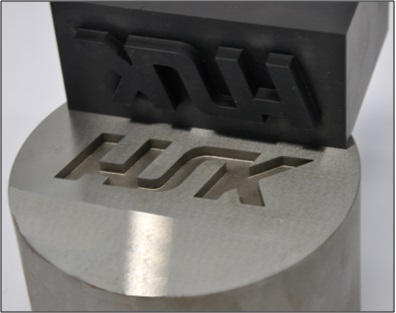

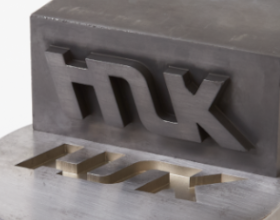

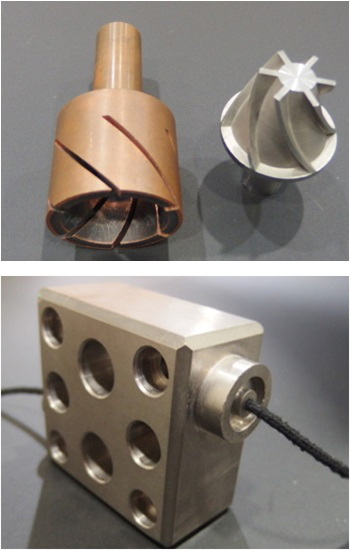

Using the electrode prepared in turning-discharge machining and electrical discharge processing, while the processing with combining the C-axis rotation, it enables the processing of such complicated shape. Processing of the "S" in the use of this processing is also available. |

|

Machining and die-sinking electrical discharge machining, they can impeller manufacture of complex shapes, such as the twisted shape and mixed-flow shape. |

|

The Company owns the microfabrication dedicated processing machine wire-cut electrical discharge machine and electric discharge machine became one. Using a wire-cut electrical discharge machining, processing a fine electrode, fine hole-slit (* minimum slit width of 0.02mm, the smallest hole diameter φ0.02mm) it is possible to process the like. Such a fine machining, as artificial fine scratches (artificial defect), it has been used to test piece or the like. |