We carry out to from the workpiece of the world's best thickness (750mm), to cutting of the foil of several tens of microns. Further we are enable the processing and twisting shape processing of special materials and new materials.

- We can consistently processing to delivery from the purchase of material.

- Available upon contract processing also happily in semi-finished products and prototypes.

- Equipment sales in conjunction to the processing content and corresponding to meet the customer's needs is possible.

- Processing track record over more than half a century.

- Japan's largest in the full-time of electrical discharge processing (metal working).

- It can be a wide range of support from micro processing to large processing.

- We realized the processing reform and cost reduction by developed in-house special-purpose machine.

|

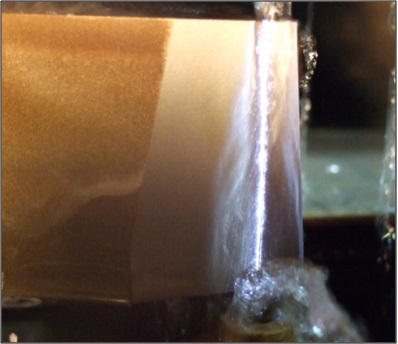

We apply applications developed rotation control and the application of the program of the wire cut. The workpiece with hardness it was not possible machining in conventional machining, we carry out processing of screw geometry and the wire cutting machining of the helical groove to it. |

|

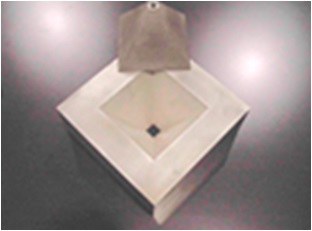

Taper angle on one side 30 degrees or more of the high angle taper processing of sample products. In the conventional it has been made by split and welding or the like, it is possible to work in one piece. |

|

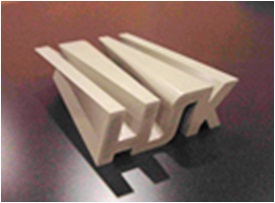

A sample of vertical different shaping what is processed into the shape of our logo, back side of the "H" is "K". In the conventional it has been made by split and welding or the like, it is possible to work in one piece. |