In the Press dies & Method development business, we have proposed a new construction method development using ZENFormer, ZENFormer nano.

We propose a significant man-hour reduction in the use of high precision press.

- We can consistently processing to delivery from the purchase of material.

- Available upon contract processing also happily in semi-finished products and prototypes.

- Equipment sales in conjunction to the processing content and corresponding to meet the customer's needs is possible.

- We developed the servo press machine of high precision and high efficiency of the world's highest level.

- We proposed the new method development and man-hour reduction plan due to the high precision servo press.

- Not only sale of press machine, can be manufactured prototypes and mass.

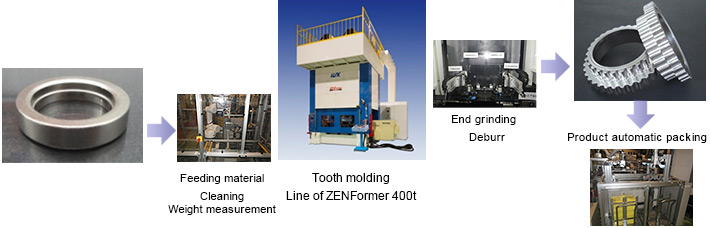

Case of two-stage cycloid gear molding by cold forging one step

|

Product |

Decelerator for automotive variable intake system |

|---|

|

Focused quality |

Profile of line of two-stage cycloid gear, Concentricity between the two-stage gear, Cylindrical degree by the gear 3-stage surface |

|---|

|

Mass production line |

By utilizing the high-precision parallel pressurization and the micron bottom dead center accuracy of ZENFormer, it molds two-stage cycloid gear from ring blank by cold forging one step. |

|---|

|

Result |

Repeatability of the contour(a few micron level), Product strength improved by work hardening, Cost reduction |

|---|

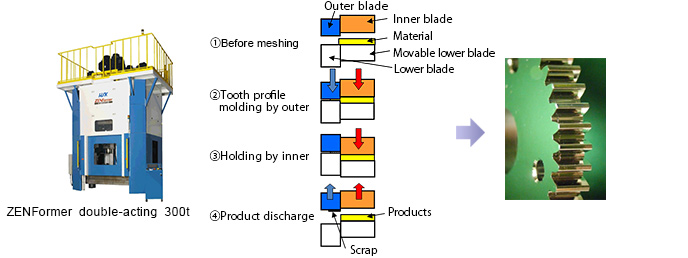

The case of shear by double-acting up and down simultaneously molding

|

Product |

Tape feeder sprocket for semiconductor chip mounter |

|---|

|

Focused quality |

The concentricity between the tooth bottom and the center reference hole is smaller than 10μm. |

|---|

|

Mass production line |

Taking advantage of the double-acting slide of ZENFormer, it pulls tooth dies simultaneously up and down. |

|---|

|

Result |

It has achieved the concentricity smaller than 10μm in the high productivity press working. |

|---|

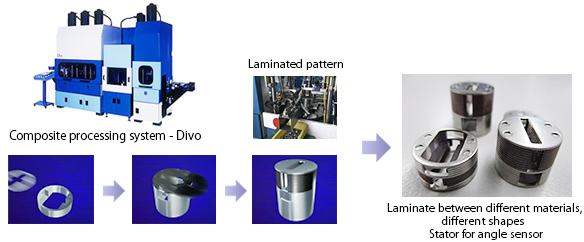

Case of Laminate processing between different materials, different shapes

|

Product |

Angle sensor for vehicle electronic throttle valve, accelerator pedal, exhaust gas recirculation valve, etc. |

|---|

|

Focused quality |

Position accuracy, Straight angle, Joint strength between magnetical laminations. |

|---|

|

Mass production line |

Laminating magnetic steel sheets and non-magnetic steel sheets alternately, and high accuracy the gap of the magnetic part. |

|---|

|

Result |

It has achieved the complex hollow three-dimensional structure by different materials in the high productivity press working. |

|---|

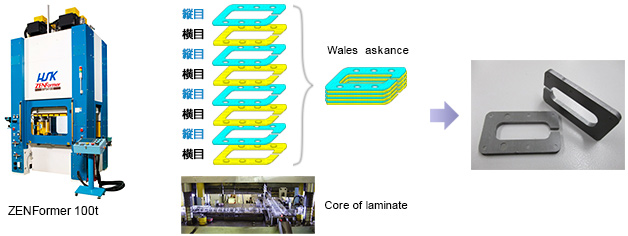

Case of Cross-laminating of oriented magnetic steel sheets

|

Product |

Automotive battery current detection sensor |

|---|

|

Focused quality |

Step accuracy of the left and right of the slit |

|---|

|

Mass production line |

Laminating of oriented electromagnetical steel sheets to be orthogonal in the rolling direction for each one. |

|---|

|

Result |

By to be orthogonal for each one and to laminate accurately electromaginetical steel sheets: it is low cost but it has insulating layer of high hardness that hurts significantly mold, it has achieved to ensure the magnetic properties and a significant material cost reduction compared to the upscale non-oriented magnetical steel sheet. |

|---|

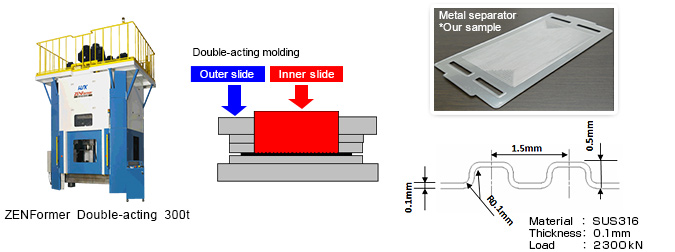

Case of high precision plane overhang by double-acting molding

|

Product |

Metal separator for fuel cell |

|---|

|

Focused quality |

Uniform overhang height accuracy and flatness in the entire flow path |

|---|

|

Molding process |

Restrainting a large area thin plate entirely uniformly by parallel control of the outer with double-acting ZENFormer, confining, and molded overhanging the entire flow path with a high accuracy by centralized load of independently driven inner. |

|---|

|

Result |

Type accurate precisely is transferred to, achieve a highly accurate overhang. |

|---|